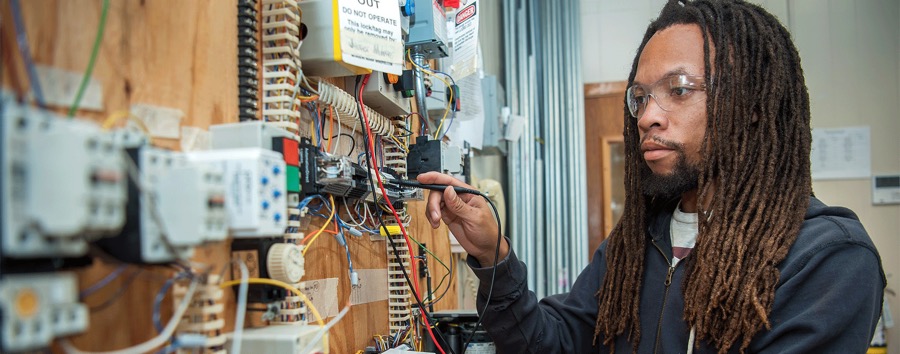

Industrial Maintenance Trades

The Industrial Maintenance Technology curriculum is a Career Technical program designed to prepare students for entry-level employment as multi-skilled maintenance technicians. Industrial maintenance trade technicians are responsible for assembling, installing, and maintaining and repairing machinery used in the manufacturing or industrial environment. Students receive basic instruction in a wide variety of areas including safety, machinery maintenance and troubleshooting/service, blueprint reading, basic welding and cutting operations, basic machining operations, fundamentals of piping and hydro-testing, and fundamentals of industrial electricity.

- College Credit Certificate

- Technical Certificate

- Technical Certificate

- A.A.S. Degree

IMM 1113 INDUSTRIAL MAINTENANCE CORE AND SAFETY - This course includes basic safety, introduction to construction math, introduction to hand and power tools, blueprint drawings, and employability and communications. Instructors for this course must be certified as an NCCER Instructor if administering the certification. (3sch. 2-hr lecture, 2-hr lab)

IMM 1243 MECHANICAL AND INDUSTRIAL MAINTENANCE I - This course includes advanced trade math, precision measuring tools, installing bearings, and installing couplings. Instructors for this course must be certified as an NCCER Instructor if administering the certification. (3 sch. 1-hr lecture, 4-hr lab)

IMM 1253 MECHANICAL INDUSTRIAL MAINTENANCE II - This course includes advanced setting baseplates and pre-alignment, conventional alignment, installing belt and chain drives, and installing mechanical seals. Instructors for this course must be certified as an NCCER Instructor if administering the certification. (3 sch. 1-hr lecture, 4-hr lab)

IMM 1214 INTRODUCTION TO INDUSTRIAL MAINTENANCE - This course includes basic tools of the trade, fasteners and anchors, oxyfuel cutting, gaskets and packing, craft-related mathematics, construction drawings, pumps and drivers, introduction to valves and test equipment, material handling, mobile and support equipment, and lubrication. Instructors for this course must be certified as an NCCER Instructor if administering the certification. (4 sch. 2-hr lecture, 4-hr lab)

IMM 1313 PRINCIPLES OF HYDRAULICS & PNEUMATICS – This course provides Instruction in basic principles of hydraulics and pneumatics and the inspection, maintenance, and repair of hydraulic and pneumatic systems. (3 sch. 2-hr lecture, 2-hr lab)

IMM 1814 ELECTRICAL INDUSTRIAL MAINTENANCE I - Advanced skills and knowledge associated with electrical systems in an industrial setting. Content includes instruction in the National Electrical Code, electrical circuits, motors, and estimating expenses for a given project. Instructors for this course must be certified as an NCCER Instructor if administering the certification. (4 sch. 2-hr lecture, 4-hr lab) Prerequisite: IMM 1113 Industrial Maintenance Core & Safety or CTE 1143 Fundamental of Construction and Manufacturing

IMM 2613 PROGRAMMABLE LOGIC CONTROLLERS - This course includes of programmable logic controllers (PLCs) in modern industrial settings. This course also includes the operating principles of PLCs and practice in the programming, installation, and maintenance of PLCs. (3 sch. 2-hr lecture, 2-hr lab)

IMM 2214 ADVANCED ELECTRICAL INDUSTRIAL MAINTENANCE - This course includes hazardous locations, electronic components, E & I drawings, motor controls, distribution equipment, transformer applications, and conductor selection and calculation. Instructors for this course must be certified as an NCCER Instructor if administering the certification. Prerequisite: IMM 1113 Industrial Maintenance Core & Safety or CTE 1143 Fundamental of Construction and Manufacturing. (4 sch. 2-hr lecture, 4-hr lab)

IMM 2424 SOLID STATE MOTOR CONTROL - This course includes principles and operation of solid state motor control. Additionally, the course includes the design, installation, and maintenance of different solid state devices for motor control. Prerequisite: IMM 1323 Motor Control Systems or IMM 1484 Industrial Control Systems and IMM 2613 Programmable Logic Controllers or Instructor Approved. (4 sch. 2-hr lecture, 4-hr lab)

IMM 2224 ADVANCED MECHANICAL INDUSTRIAL MAINTENANCE - This course includes temporary grounding, layout and installation of tubing and piping systems, machine bending of conduit, hydraulic controls, pneumatic controls, and motor-operated valves. Instructors for this course must be certified as an NCCER Instructor if administering the certification. (4 sch. 2-hr lecture, 4-hr lab Prerequisite: IMM 1113 Industrial Maintenance Core & Safety or CTE 1143 Fundamental of Construction and Manufacturing

IMM 1734 MAINTENANCE WELDING AND METAL - This course includes different metals and their properties and in basic SMAW welding and oxy-fuel cutting and brazing. Components of this course are adopted from the NCCER Welding Level 1 Certification. Instructors for this course must be certified as an NCCER Instructor if administering the certification. (4 sch. 1-hr lecture, 6-hr lab) Prerequisite: None

IMM 1173 MOTOR MAINTENANCE TROUBLESHOOTING - This course includes the principles and practice of electrical motor repair. Topics on the disassembly/assembly and preventive maintenance of common electrical motors are discussed. (3sch. 2-hr lecture, 2-hr lab) Prerequisite: Instructor Approved

IMM 1163 ELECTRICAL INDUSTRIAL MAINTENANCE II - This course includes process mathematics, hand bending, tubing, clean purge, and test tubing and piping systems, instrument drawings and documents (part one), conductors and cables, and conductors terminations and splices. Instructors for this course must be certified as an NCCER Instruct if administering the certification. (3 sch. 1-hr lecture, 4-hr lab) Prerequisite: IMM 1113 Industrial Maintenance Core & Safety or CTE 1143 Fundamental of Construction and Manufacturing

IMM 1323 MOTOR CONTROL SYSTEMS - This course includes the Installation of different motor control circuits and devices. Emphasis is placed on developing the student’s ability to diagram, wire, and troubleshoot the different circuits and mechanical control devices. (3 sch. 2-hr lecture, 2-hr lab) Prerequisite: IMM 1153 Electrical Industrial Maintenance I and 1163 Electrical Industrial Maintenance II or Instructor Approved

Helpful Links

Helpful Links

Navigation

- Office of Career Tech

- Mission & Core Values

- Pathways

- National Technical Honor Society

- Automotive Technology

- Barbering

- Brick, Block and Stone Masonry

- Business & Office Related Technology

- Carpentry

- Collision Repair

- Commercial Truck Driving

- Cosmetology

- Culinary Arts

- Early Childhood Development Technology

- Electrical Technology

- HVAC and Refrigeration

- Industrial Maintenance Trades

- Welding & Cutting Technology

Contact Information

Advisor: E Bell

Phone: 662. 621.4170

Email: edbell@coahomacc.edu

Counselor: M. Gatewood

Phone: 662.621.4849

Email: mgatewood@coahomacc.edu